What Causes Air Bubbles In A Model . · increase the back pressure. for products that require airtight seals or precise flow paths, air bubbles can disrupt these critical features,. · do not set the injection volume too high. when the pour doesn’t go smoothly, the model may have voids, broken teeth, or chalky spots owing to. if it is a gas bubble, the gas will warm up and expand, raising the surface, and often will pop as the part surface. I have some resin parts i am going to use on a build and i was. This can happen when the resin is poured too. If air is trapped during the mold cavity filling process, the shape, gate. full name:mark mason. the most common cause of air bubbles in a model is trapped air.

from www.webexhibits.org

full name:mark mason. for products that require airtight seals or precise flow paths, air bubbles can disrupt these critical features,. I have some resin parts i am going to use on a build and i was. · increase the back pressure. · do not set the injection volume too high. If air is trapped during the mold cavity filling process, the shape, gate. the most common cause of air bubbles in a model is trapped air. when the pour doesn’t go smoothly, the model may have voids, broken teeth, or chalky spots owing to. if it is a gas bubble, the gas will warm up and expand, raising the surface, and often will pop as the part surface. This can happen when the resin is poured too.

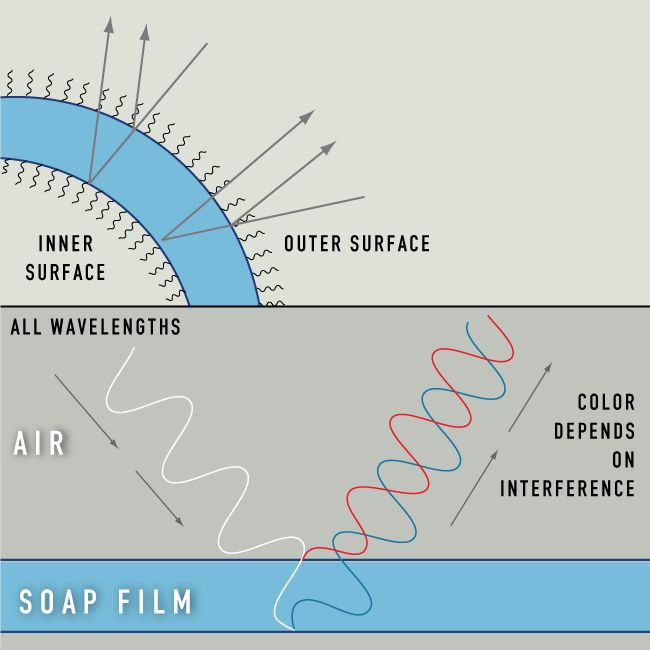

Bubbles Causes of Color

What Causes Air Bubbles In A Model if it is a gas bubble, the gas will warm up and expand, raising the surface, and often will pop as the part surface. · do not set the injection volume too high. If air is trapped during the mold cavity filling process, the shape, gate. the most common cause of air bubbles in a model is trapped air. This can happen when the resin is poured too. for products that require airtight seals or precise flow paths, air bubbles can disrupt these critical features,. if it is a gas bubble, the gas will warm up and expand, raising the surface, and often will pop as the part surface. full name:mark mason. · increase the back pressure. I have some resin parts i am going to use on a build and i was. when the pour doesn’t go smoothly, the model may have voids, broken teeth, or chalky spots owing to.

From www.comsol.fr

Simulate ThreePhase Flow with a New Phase Field Interface COMSOL Blog What Causes Air Bubbles In A Model I have some resin parts i am going to use on a build and i was. full name:mark mason. for products that require airtight seals or precise flow paths, air bubbles can disrupt these critical features,. · increase the back pressure. This can happen when the resin is poured too. the most common cause of air. What Causes Air Bubbles In A Model.

From www.ecomolding.com

What causes air bubbles or voids in injection molding? What Causes Air Bubbles In A Model when the pour doesn’t go smoothly, the model may have voids, broken teeth, or chalky spots owing to. if it is a gas bubble, the gas will warm up and expand, raising the surface, and often will pop as the part surface. I have some resin parts i am going to use on a build and i was.. What Causes Air Bubbles In A Model.

From www.pinterest.com

Removing Air Bubbles While Canning in 2022 Canning, Bubbles, Home food What Causes Air Bubbles In A Model for products that require airtight seals or precise flow paths, air bubbles can disrupt these critical features,. · do not set the injection volume too high. when the pour doesn’t go smoothly, the model may have voids, broken teeth, or chalky spots owing to. · increase the back pressure. If air is trapped during the mold cavity. What Causes Air Bubbles In A Model.

From vehiclefreedom.com

Bubbles in Transmission Fluid (Causes & Fixes) Vehicle Freedom What Causes Air Bubbles In A Model full name:mark mason. when the pour doesn’t go smoothly, the model may have voids, broken teeth, or chalky spots owing to. if it is a gas bubble, the gas will warm up and expand, raising the surface, and often will pop as the part surface. This can happen when the resin is poured too. for products. What Causes Air Bubbles In A Model.

From www.ufluidix.com

Bubbles in Microfluidics How They Form and How to Avoid Them What Causes Air Bubbles In A Model This can happen when the resin is poured too. when the pour doesn’t go smoothly, the model may have voids, broken teeth, or chalky spots owing to. for products that require airtight seals or precise flow paths, air bubbles can disrupt these critical features,. the most common cause of air bubbles in a model is trapped air.. What Causes Air Bubbles In A Model.

From salvagesecretsblog.com

A Guide to Air Bubble Extraction in Epoxy Resin Salvage Secrets What Causes Air Bubbles In A Model the most common cause of air bubbles in a model is trapped air. if it is a gas bubble, the gas will warm up and expand, raising the surface, and often will pop as the part surface. · do not set the injection volume too high. when the pour doesn’t go smoothly, the model may have voids,. What Causes Air Bubbles In A Model.

From carfueladvisor.com

What Causes Air Bubbles in Engine Oil? Explained Car Fuel Advisor What Causes Air Bubbles In A Model · do not set the injection volume too high. when the pour doesn’t go smoothly, the model may have voids, broken teeth, or chalky spots owing to. · increase the back pressure. If air is trapped during the mold cavity filling process, the shape, gate. I have some resin parts i am going to use on a build. What Causes Air Bubbles In A Model.

From arstechnica.com

Two new papers explore the complicated physics behind bubbles and foams What Causes Air Bubbles In A Model full name:mark mason. · do not set the injection volume too high. · increase the back pressure. I have some resin parts i am going to use on a build and i was. the most common cause of air bubbles in a model is trapped air. This can happen when the resin is poured too. for. What Causes Air Bubbles In A Model.

From www.researchgate.net

(PDF) A review of VOF methods for simulating bubble dynamics What Causes Air Bubbles In A Model full name:mark mason. for products that require airtight seals or precise flow paths, air bubbles can disrupt these critical features,. the most common cause of air bubbles in a model is trapped air. · increase the back pressure. when the pour doesn’t go smoothly, the model may have voids, broken teeth, or chalky spots owing. What Causes Air Bubbles In A Model.

From www.bigstockphoto.com

Air Bubbles Rise Image & Photo (Free Trial) Bigstock What Causes Air Bubbles In A Model when the pour doesn’t go smoothly, the model may have voids, broken teeth, or chalky spots owing to. I have some resin parts i am going to use on a build and i was. the most common cause of air bubbles in a model is trapped air. If air is trapped during the mold cavity filling process, the. What Causes Air Bubbles In A Model.

From www.aquariadise.com

Bubbles on Fish Tank Glass The Causes and Solutions What Causes Air Bubbles In A Model if it is a gas bubble, the gas will warm up and expand, raising the surface, and often will pop as the part surface. · do not set the injection volume too high. for products that require airtight seals or precise flow paths, air bubbles can disrupt these critical features,. · increase the back pressure. full. What Causes Air Bubbles In A Model.

From www.microlit.com

How to remove air bubbles from any liquid handling instrument? Microlit What Causes Air Bubbles In A Model the most common cause of air bubbles in a model is trapped air. If air is trapped during the mold cavity filling process, the shape, gate. full name:mark mason. if it is a gas bubble, the gas will warm up and expand, raising the surface, and often will pop as the part surface. · do not set. What Causes Air Bubbles In A Model.

From www.figma.com

Air bubbles, stunning abstract shapes Figma Community What Causes Air Bubbles In A Model full name:mark mason. If air is trapped during the mold cavity filling process, the shape, gate. the most common cause of air bubbles in a model is trapped air. for products that require airtight seals or precise flow paths, air bubbles can disrupt these critical features,. This can happen when the resin is poured too. I have. What Causes Air Bubbles In A Model.

From www.dreamstime.com

Air Bubbles Rising Water Surface Closeup. Bubbling Mineral Liquid in What Causes Air Bubbles In A Model · increase the back pressure. when the pour doesn’t go smoothly, the model may have voids, broken teeth, or chalky spots owing to. If air is trapped during the mold cavity filling process, the shape, gate. I have some resin parts i am going to use on a build and i was. This can happen when the resin. What Causes Air Bubbles In A Model.

From poolmarvel.com

Pool Bubbles Air Bubbles Coming Out of Pool Jets Pool Marvel What Causes Air Bubbles In A Model full name:mark mason. If air is trapped during the mold cavity filling process, the shape, gate. if it is a gas bubble, the gas will warm up and expand, raising the surface, and often will pop as the part surface. for products that require airtight seals or precise flow paths, air bubbles can disrupt these critical features,.. What Causes Air Bubbles In A Model.

From www.houstonchronicle.com

Risk of embolism from air bubble in IV line is minimal What Causes Air Bubbles In A Model the most common cause of air bubbles in a model is trapped air. I have some resin parts i am going to use on a build and i was. If air is trapped during the mold cavity filling process, the shape, gate. when the pour doesn’t go smoothly, the model may have voids, broken teeth, or chalky spots. What Causes Air Bubbles In A Model.

From www.youreyesinfocus.com

Have An Air Bubble Under Your Scleral Lens? Read These Tips To Avoid What Causes Air Bubbles In A Model full name:mark mason. for products that require airtight seals or precise flow paths, air bubbles can disrupt these critical features,. the most common cause of air bubbles in a model is trapped air. when the pour doesn’t go smoothly, the model may have voids, broken teeth, or chalky spots owing to. · do not set the. What Causes Air Bubbles In A Model.

From www.researchgate.net

States of bubbles motion in two kinds of pore channels a,b) Bubble What Causes Air Bubbles In A Model · do not set the injection volume too high. the most common cause of air bubbles in a model is trapped air. if it is a gas bubble, the gas will warm up and expand, raising the surface, and often will pop as the part surface. when the pour doesn’t go smoothly, the model may have voids,. What Causes Air Bubbles In A Model.